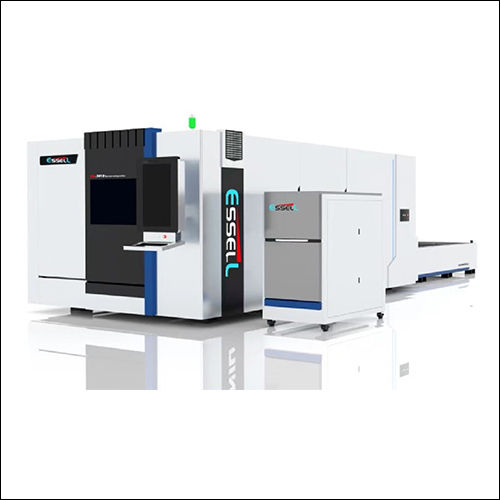

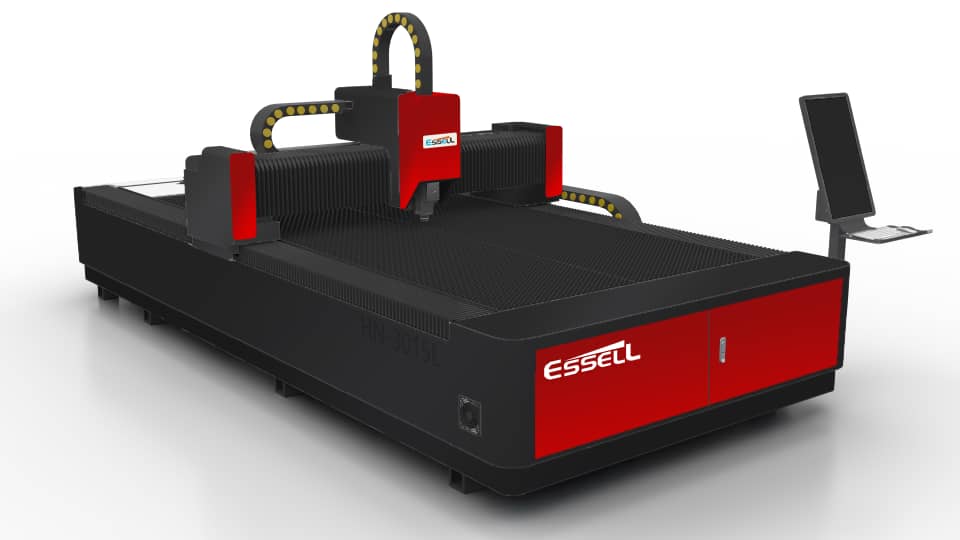

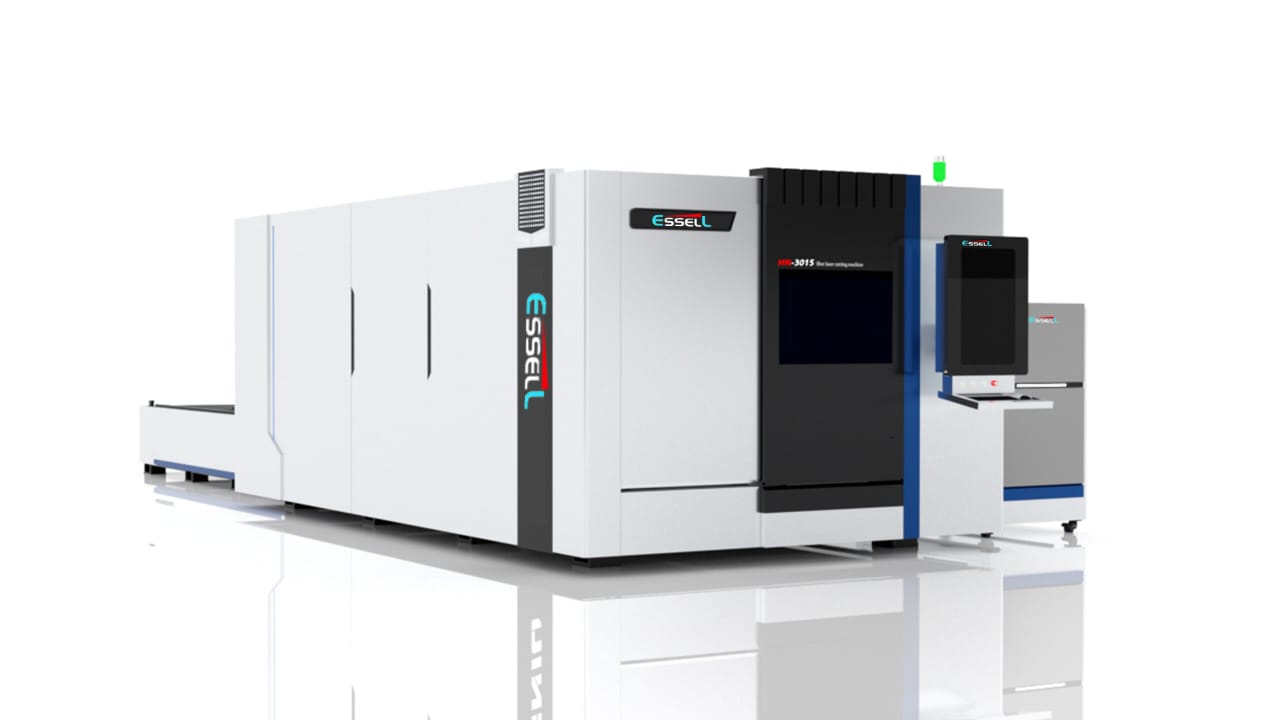

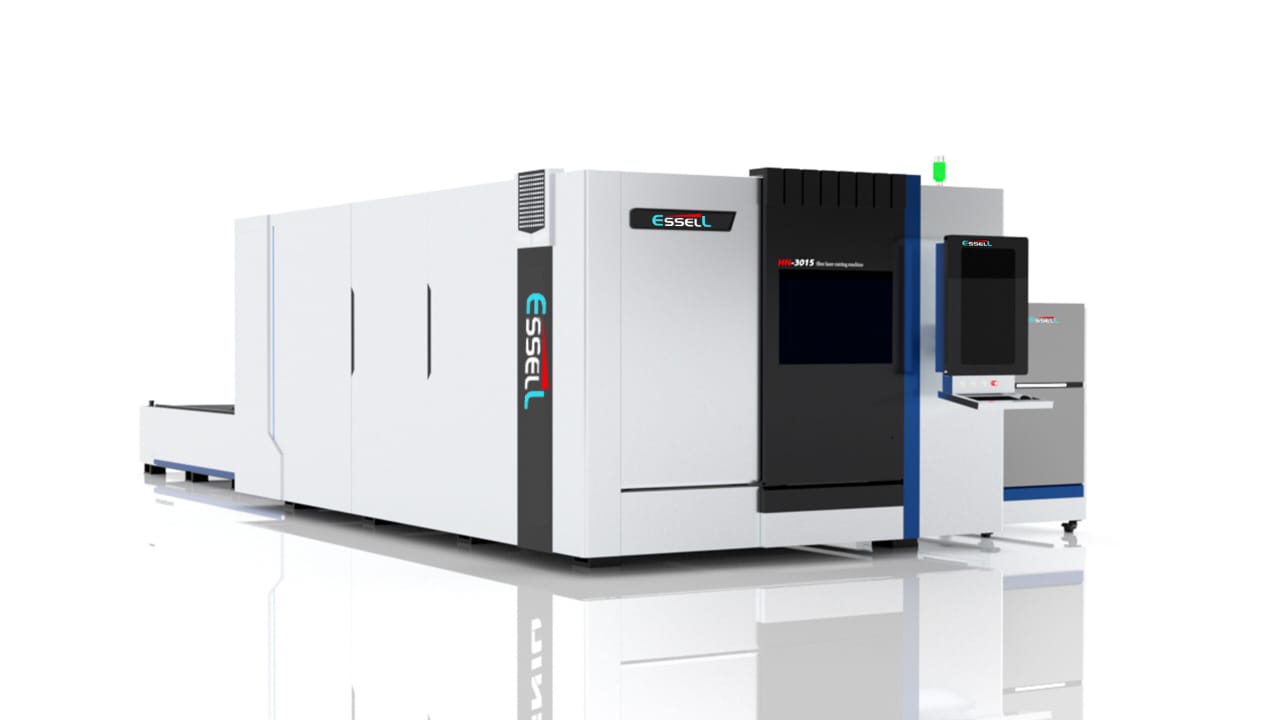

12KW ST,DT Fiber Laser Metal Cutting Machine

12KW ST,DT Fiber Laser Metal Cutting Machine Specification

- Product Type

- 12KW ST,DT Fiber Laser Metal Cutting Machine

- Cutting Thickness

- 35 Millimeter (mm)

- Control Software

- CNC CYPCUT 2000

- Weight (kg)

- 19.0 Tonne

- Feature

- ], [

- Warranty

- 2 year

12KW ST,DT Fiber Laser Metal Cutting Machine Trade Information

- Payment Terms

- [, ]

- Supply Ability

- 10 Per Month

- Delivery Time

- 10 Days

- Packaging Details

- SEA-WORTHY WOODEN PACKAGING

- Main Export Market(s)

- [, ]

- Main Domestic Market

- [, ]

About 12KW ST,DT Fiber Laser Metal Cutting Machine

The Optical Fiber as the Laser Medium, the Optical Conversion Efficiency of Pump Light Energy in to Common Wavelength Material Processing (1069-1090nm) Up to 50%; the Total Electro-optic Commonly of Fiber Laser Conversion Efficiency Up to 30% or More, More Higher Than Carbon Dioxide Glass(15-20%), (6-10%) for Carbon Dioxide Radio Frequency Laser (6-10%), Comparative Data: Lamp-pumped Cutting Machine 650w Total Power Is About 30kw/hour,the Total Power of the 800w Fiber Laser Cutting Machine Is Not More Than 8kw, You Can Calculate How Many Power Cost You Can Save One Year.Maintenance-free (Low Maintenance Costs):

All-fiber Laser Optical Path Entirely Composed of Fibers and Fiber-optic Components, Welding Technology Using Optical Fiber Connection Between the Optical Fiber and Fiber Optic Components, the Entire Optical Path Is Completely Enclosed in the Optical Fiber Waveguide. Once This Natural All Closed Optical Path Is Formed, Without Additional Isolation Measures Can Be Self-contained, Isolated From the External Environment to Achieve. Resonator Fiber Grating Replaces the Lens Structure, There Is No Lens Contamination, Distortion and So on, So That in Case of Proper Use of Fiber Lasers, Basically No Maintenance.

Integrated Use of Low Cost:

Fiber Laser Has Excellent Thermal Performance, High Electro-optical Efficiency, Saving Water and Electricity, Its Important to Maintain the Amount of Money and Time, Improve Work Efficiency. Maintenance-free and Long-term Use Up to 100,000 Hours Can Save a Lot of Money and Maintenance Time and Improve Work Efficiency.

FAQs of 12KW ST,DT Fiber Laser Metal Cutting Machine:

Q: What is the maximum cutting thickness of the 12KW ST,DT Fiber Laser Metal Cutting Machine?

A: The maximum cutting thickness of the 12KW ST,DT Fiber Laser Metal Cutting Machine is 35 millimeters (mm).Q: What is the control software used in this machine?

A: The 12KW ST,DT Fiber Laser Metal Cutting Machine uses CNC CYPCUT 2000 control software.Q: What is the weight of the machine?

A: The 12KW ST,DT Fiber Laser Metal Cutting Machine weighs 19.0 tonnes.Q: What is the warranty period for this machine?

A: The machine comes with a warranty period of 2 years.Q: Is this machine suitable for cutting metals with high precision?

A: Yes, the 12KW ST,DT Fiber Laser Metal Cutting Machine is designed for high-precision metal cutting tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Cutting Machines Category

2kw CNC Cutting Machine ine

Price 3500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Fiber Laser Cutting Machine

Warranty : 1 Year

Automatic Grade : Automatic

Exchange Table Fiber Laser Cutting Machine

Price 3300000.0 INR

Minimum Order Quantity : 1

Product Type : Exchange Table Fiber Laser Cutting Machine

Warranty : 2 year

Material : [, ', M, e, t, a, l, ', ]

Stainless Steel Fiber Laser Cutting Machine

Price 3500000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Stainless Steel Fiber Laser Cutting Machine

Warranty : 1 Year

Automatic Grade : Automatic

Material : Metal

Industrial Fiber Laser Metal Cutting Machine, Model Name/Number: ESS LC ST 3015

Price 2200000.0 INR

Minimum Order Quantity : 1

Product Type : Industrial Fiber Laser Metal Cutting Machine, Model Name/Number: ESS LC ST 3015

Warranty : 2 year

Material : ], [, ', M, e, t, a, l, '

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry