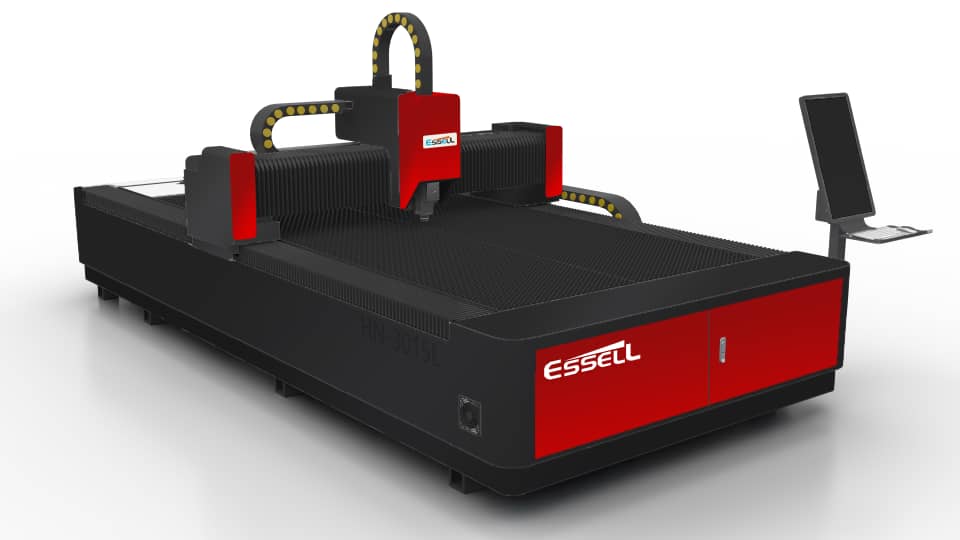

Fiber Laser Cutting Machine

Price 3200000 INR/ Unit

Fiber Laser Cutting Machine Specification

- Laser Type

- CO2

- CNC Or Not

- Normal

- Automatic Grade

- Semi Automatic

- Cooling Mode

- Air Cooling

- Control System

- Frequency Speed Control

Fiber Laser Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Fiber Laser Cutting Machine

Keeping in mind the end goal to meet the differing necessities of our regarded customers, we are occupied with giving a broad arrangement of Fabric Laser Cutting Machine as the reliable manufacturer, supplier and exporter globally. The possessed machines are widely appreciated among our clients for their qualities and performance. These machines are made by our specialists, using the high grade quality material and developed technology with the help of experienced team of employes. Our profitable customer can buy this Fiber Laser Cutting Machine at low costs in the guaranteed time span.

Key Features:

- High tensile

- Well professed team

- Ideal usefulness

- Very dependable in work

- Marking materials:

- Metal used for marking are:

- Stainless steel,high-grade steel ,steel,carbon steel

- Copper

- Iron

- Ferrous metal

- Magnesium

- Aluminum

- Brass

- Gold

- Silver

- Platinum

- Palladium

- Titanium.

- Plastics: Rubber,Bakelite,PVC,Styrene.

- Marking contents:

- Time&date marking

- Logo marking

- Artwork Marking

- Engraving

- Finesse higher areas,such as jewelry,watches,mold,bitmap marking

- Material Removal, Coat Layer Removal

- ID and Serial Numbers Marking

Frequently Asked Questions:

1) Which is better CO2 or fiber laser?

Fiber can cut copper, brass and aluminum much better and more safely than CO2 because the beam is more readily absorbed and not reflected. Fiber laser operating costs are typically half of what a CO2 system can offer due to the lower electrical consumption and high electrical efficiency of Fiber lasers.

2) How long does a fiber laser last?

around 100,000 hours

Specification

| Usage/Application | Digital Fabric |

| Cutting Material | Fiber |

| Brand | Ledan |

| Fix Position Precision | Automatic Edge Searching |

| Power Source | Electric |

| Frequency | 50 Hz |

| Cutting Thickness | 14mm |

| Automation Grade | Automatic |

| Voltage | 440 V |

| Machine Type | Fiber Laser Cutting Machine |

| Working Area | 2.5 X 2feet |

| Cutting Speed | 130m/min |

| Laser Power | 2000 W |

| Model Name/Number | DFCS-1500 |

FAQs of Fiber Laser Cutting Machine:

Q: What type of laser does the Fiber Laser Cutting Machine utilize?

A: The Fiber Laser Cutting Machine utilizes a CO2 laser.Q: Is this machine fully automatic?

A: No, the Fiber Laser Cutting Machine is semi-automatic.Q: What control system is used in this machine?

A: The Fiber Laser Cutting Machine operates on a Frequency Speed Control system.Q: What cooling mode does the machine employ?

A: The Fiber Laser Cutting Machine uses air cooling for temperature regulation.Q: Is this machine equipped with CNC capabilities?

A: No, the Fiber Laser Cutting Machine is not CNC-enabled; it is categorized as normal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Cutting Machines Category

Exchange Table Fiber Laser Cutting Machine

Price 3300000.0 INR

Minimum Order Quantity : 1

Product Type : Exchange Table Fiber Laser Cutting Machine

Warranty : 2 year

Material : [, ', M, e, t, a, l, ', ]

Weight (kg) : 1500 Kilograms (kg)

Automatic Fiber Laser Cutting Machine

Price 3200000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Automatic Fiber Laser Cutting Machine

Warranty : 1 Year

Stainless Steel Fiber Laser Cutting Machine

Price 3500000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Stainless Steel Fiber Laser Cutting Machine

Warranty : 1 Year

Material : Metal

Single Table Fiber Laser Cutting Machine 1000W/1500W/2000W/3000W upto 6000 W

Price 2400000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Single Table Fiber Laser Cutting Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry